Our Expertise Transforming Plastics into Innovative Solutions

At Puebro, we possess a wealth of expertise in various plastic processing techniques, allowing us to transform raw materials into a wide range of high-quality products. Our skilled team and advanced machinery ensure precision, efficiency, and exceptional results in every project.

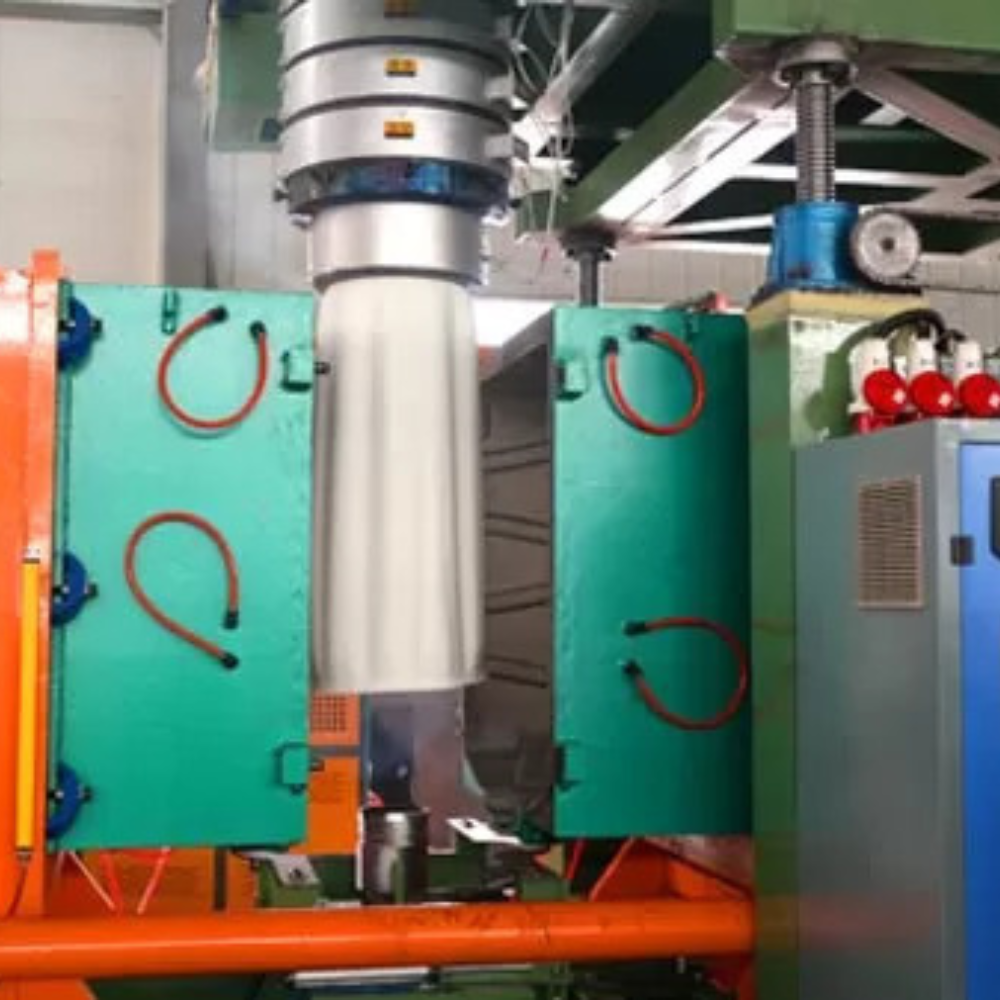

1. Blow Film Extrusion:

- Multi-Layer Film Extrusion: Creating films with multiple layers, each with specific properties to enhance functionality and performance.

- High-Capacity Production: Meeting large-scale demands with efficient and reliable extrusion lines.

- Precise Thickness Control: Ensuring consistent film thickness for optimal performance in various applications.

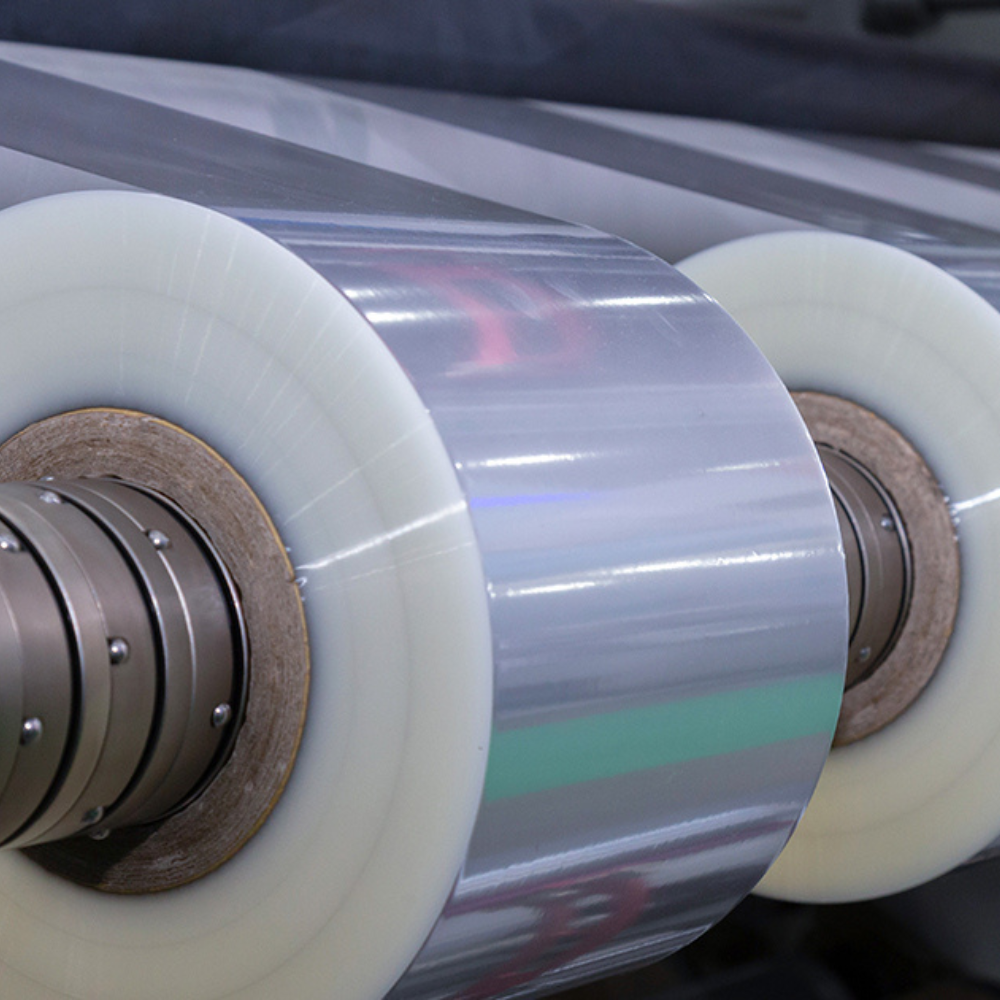

2. Film Casting:

We specialize in producing high-quality cast films with superior clarity and surface finish. Our capabilities include:

- Precise Thickness Control: Creating films with uniform thickness for demanding applications.

- High-Capacity Production: Meeting large-scale demands with efficient and reliable casting lines.

- Specialty Film Production: Producing films with specific properties, such as high barrier properties or UV resistance.

3. Blow Molding:

Our expertise in blow molding allows us to create hollow plastic products with various shapes and sizes. We specialize in:

- High-Volume Production: Efficiently manufacturing large quantities of bottles, containers, and other hollow products.

- Precise Wall Thickness Control: Ensuring consistent wall thickness for product strength and durability.

- Complex Shape Molding: Creating products with intricate designs and features.

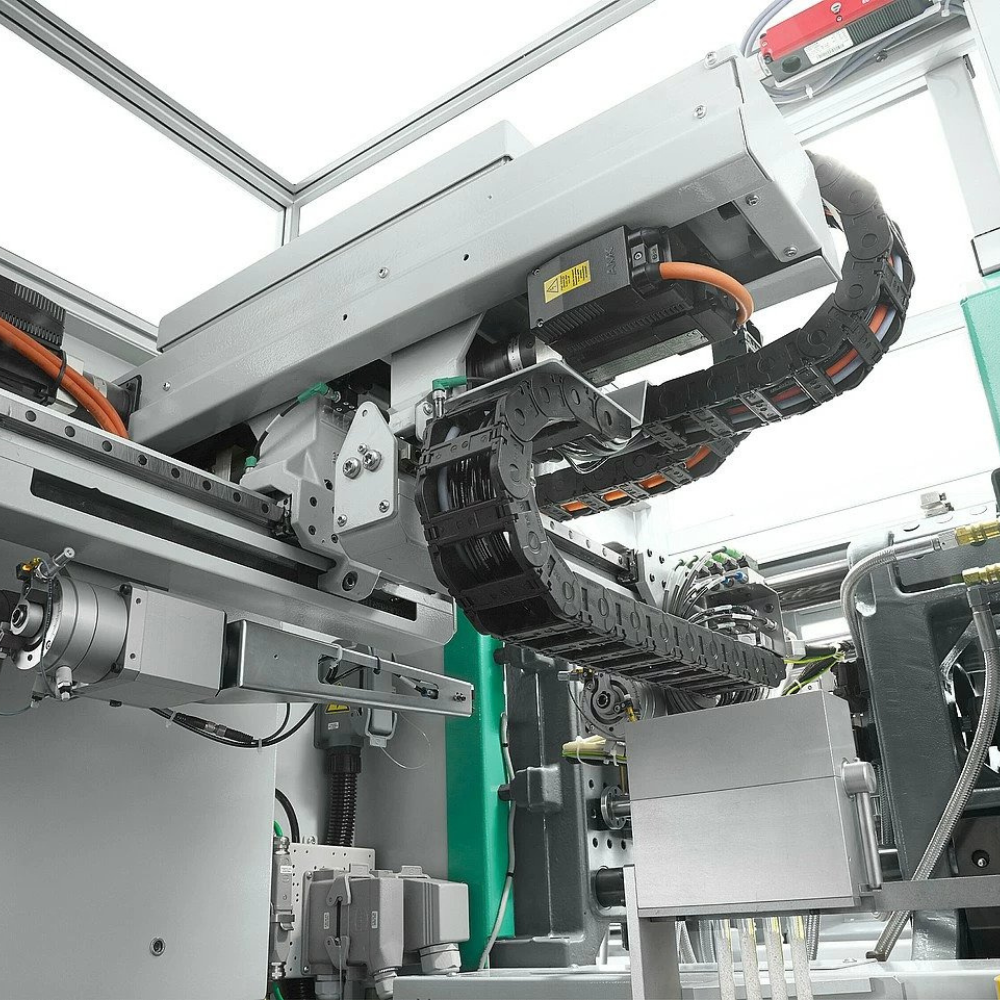

4. Injection Molding:

We leverage advanced injection molding techniques to produce complex plastic parts with high precision. Our capabilities include:

- High-Volume Production: Efficiently manufacturing large quantities of intricate plastic components.

- Intricate Part Design: Producing parts with complex shapes, fine details, and tight tolerances.

- Diverse Material Compatibility: Working with various plastic resins to meet specific product requirements.

5. Supporting Processes:

We possess expertise in various supporting processes that enhance the quality and functionality of our products, including:

- Printing: Applying high-quality printing on films and other products for branding, labeling, and decorative purposes.

- Slitting: Precisely cutting films to specific widths for efficient processing and diverse applications.

- Sealing & Cutting: Creating secure seals and precise cuts on films and pouches for optimal product packaging.